GROSS BRIQUETTING PRESSES

GROSS Briquetting press for shavings, wood dust and wood chips type GP 400 M

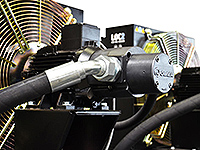

GP 400 M with chip turner and feed screw

Economical briquetting technology, reliable and powerful

The GROSS briquetting presses with their flexible application possibilities can produce briquettes from all kinds of wood materials with low bulk density, for example from sawdust, chipping chips or shavings. Thanks to sophisticated technology, these materials can be economically converted into compact briquettes and achieve an enormous volume reduction. Thanks to efficient equipment, the GROSS briquetting presses can also be used optimally in the area of the briquetting of paper and paper dust, polystyrene, light metal or similar materials.

The GROSS briquetting presses with their flexible application possibilities can produce briquettes from all kinds of wood materials with low bulk density, for example from sawdust, chipping chips or shavings. Thanks to sophisticated technology, these materials can be economically converted into compact briquettes and achieve an enormous volume reduction. Thanks to efficient equipment, the GROSS briquetting presses can also be used optimally in the area of the briquetting of paper and paper dust, polystyrene, light metal or similar materials.

GP 400 M with option agitator and chip container

Briquetting press type GP 400 M for shavings, wood dust and wood chips

Suitable materials: softwood wood shavings, dust & wood chips

Residual moisture of the material: Residual moisture max. 17%

Dimensions of the material: Max. 10 mm +/- 2mm

Material characteristics: loose, clean and free from foreign substances

Material feed: Via conveyor belt or conveyor screw GROSS

Nominal throughput: Up to max. 3000 kg / day

Machine running time up to max. 10 h / day running time

Suitable materials: softwood wood shavings, dust & wood chips

Residual moisture of the material: Residual moisture max. 17%

Dimensions of the material: Max. 10 mm +/- 2mm

Material characteristics: loose, clean and free from foreign substances

Material feed: Via conveyor belt or conveyor screw GROSS

Nominal throughput: Up to max. 3000 kg / day

Machine running time up to max. 10 h / day running time

Details:

Practical example

Briquetting press GP 400 M in cooperation with a GAZ / GHM crushing plant - pre-comminution by a single-shaft crusher - post-comminution with a cutting mill for the preparation of the material to be pressed.

End product Wood briquettes

Packing of wooden briquettes

Wooden briquettes wrapped on pallet

Briquette transport rail

Technical specification GP 400 M

| Main dimensions (L x B x H): | approx. 1.800 x 1.800 x 1.900 mm |

| Drive power: | 30 kW |

| Briquette dimensions: | 150 x 60 bis 95 mm |

| Hydraulic oil: | approx. 900 l |

| Ambient temperature: | +5°C till 45°C |

| Throughput: | from till max. 400 kg/h* |

| Painting: | GROSS Standard RAL 5017 / 7016 |

| Power consumption: | 400 V +/- 5% / 50 Hz |

| Weight: | approx. 4.200 kg |

* The throughput is strongly material-dependent. Average values are given

* Depending on mixing ratio and moisture content!

Including single components briquetting press GP 400 M

Downloads